Cheap PriceList for Aluminium 6063 T6 Tube Anodized - Aluminum ingot – Wanlutong Detail:

Brand name: wanlutong.

Origin: shandong, China.

Product name: aluminum ingot.

Non-standard specifications can be customized.

ALUMINUM INGOT

Description:

The raw material for industrial aluminum ingots in our daily industry is called aluminum ingots. According to the national standard (GB/T 1196-2008), it should be called “remelting aluminum ingot”. It was produced by electrolysis with alumina – cryolite.

There are two main types of aluminum ingots in industrial application: cast aluminum alloy and deformed aluminum alloy.

Casting aluminum and aluminum alloy casting is the casting method. Deformed aluminium and aluminum alloys are processed products of aluminum by means of pressure processing: board, tape, foil, pipe, rod, type, line and forgings.

According to the national standard, “the chemical composition of the remelting aluminum ingot is divided into eight brands, namely Al99.90, Al99.85, Al99.70, Al99.60, Al99.50, Al99.00, Al99.7E, Al99.6E” (note: the number after Al is aluminum content).

Aluminum ingots are divided into three types: aluminum ingots, high purity aluminum ingots and aluminum ingots.

Aluminum alloy ingots are made of pure aluminum and recycled aluminum, and other elements are added according to international standards or special requirements, such as silicon (Si), copper (Cu), magnesium (Mg), iron (Fe)… To improve the alloy of pure aluminum in casting, chemical and physical insufficiency.

Features:

Al-si alloy (Al – Si), good casting properties, such as good liquidity, good air tightness, small shrinkage rate, and tend to be small, warm after metamorphism and heat treatment, with good mechanical properties, physical properties, corrosion resistance and medium machining performance, is the aluminum alloy casting in most varieties and the most widely used type of alloy.

ZL101(A) alloy ZL101 alloy has good air titility, fluidity and thermal cracking resistance. It has medium mechanical properties, welding performance and corrosion resistance. It is simple in composition and easy to cast.

ZL104 alloy ZL104 alloy has good air tightness, liquidity and thermal crack resistance, high strength, corrosion resistance, good welding performance and machining performance, but low heat resistant strength, easy to produce tiny pores, casting process is relatively complicated. Therefore, it is mainly used to manufacture sand type metal casting with high load.

ZL105 alloy ZL105 alloy of high mechanical properties, castability and welding performance is satisfactory, machinability and heat intensity is better than ZL104 alloy, but low plasticity, corrosion stability is not high, suitable for all kinds of casting method.

Uses:

High corrosion resistance of parts, such as frame, pedestal, rods and accessories, engine piston, brake block, pulley, pumps and other wear-resistant parts, waveguide and high pressure valves, hydraulic line, plane hanging rack and high-speed rotor blade, ocean ship the parts, etc.

Chemical composition:

|

Gradep |

Chemical Composition % |

|||||||||

|

AI ≥ |

impurities ≤ |

|||||||||

|

Fe |

Si |

Cu |

Mg |

Zn |

Ti |

Mn |

Ga |

Each other |

||

| A199.995 | 99.995 | 0.0010 | 0.0010 | 0.0015 | 0.0015 | 0.0005 | 0.0005 | 0.0007 | 0.0010 | 0.0010 |

| A199.993A | 99.993 | 0.0010 | 0.0010 | 0.0030 | 0.0020 | 0.0010 | 0.0010 | 0.0008 | 0.0010 | 0.0010 |

| A199.993 | 99.993 | 0.0015 | 0.0015 | 0.0030 | 0.0025 | 10..10 | 0.0010 | 0.0010 | 0.0012 | 0.0010 |

| A199.99 | 99.990 | 0.0030 | 0.0030 | 0.0050 | 0.0030 | 0.0010 | 0.0010 | 0.0010 | 0.0015 | 0.0010 |

| A199.99 | 99.990 | 0.0030 | 0.0030 | 0.0050 | 0.0030 | 0.0010 | 0.0010 | 0.0010 | 0.0015 | 0.0010 |

| A199.98 | 99.980 | 0.0070 | 0.0070 | 0.0080 | 0.0030 | 0.0020 | 0.0020 | 0.0015 | 0.0020 | 0.0030 |

| A199.95 | 99.950 | 0.0200 | 0.0200 | 0.0100 | 0.0050 | 0.0050 | 0.0050 | 0.0020 | 0.0020 | 0.0100 |

Correspondence:

|

Chinese and foreign remelting aluminum ingot control. |

||||

|

China GB/T 1196-2008 |

Japan JIS H 2102:1968 |

America AA(Aluminum association):1982 |

International standard ISO 115:2003 |

Europe EN 576:2003 |

|

A199.90 |

Special level 1 |

P0507B |

A199.9 |

—— |

|

A199.85 |

Special level 2 |

P1015A |

—— |

—— |

|

A199.70 |

Level 1 |

P1020D |

A199.7 |

A199.70 |

|

A199.60 |

—— |

P1520F |

—— |

—— |

|

A199.50 |

Level 2 |

—— |

A199.5 |

—— |

|

A199.00 |

Level 3 |

990A (ASTM B37:2003) |

—— |

—— |

|

A199.7E |

—— |

—— |

A199.7E |

A199.7E |

Product detail pictures:

Related Product Guide:

Copper Tubing Coils

Repairing Copper Tubing

Cheap PriceList for Aluminium 6063 T6 Tube Anodized - Aluminum ingot – Wanlutong, The product will supply to all over the world, such as: , , ,

-

ODM Manufacturer Tungsten Bars For Sale - Pure...

-

China New Product Makeup Tin Box Packaging - P...

-

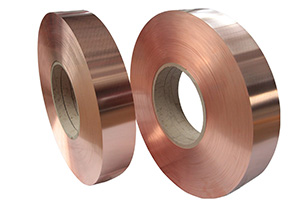

factory Outlets for Jewelry Brass Plates - Cop...

-

Chinese Professional Aluminum Pipe For Hair Col...

-

High definition Round Coupler - Pure copper fo...

-

OEM/ODM China Color Coated Embossed Aluminum Co...