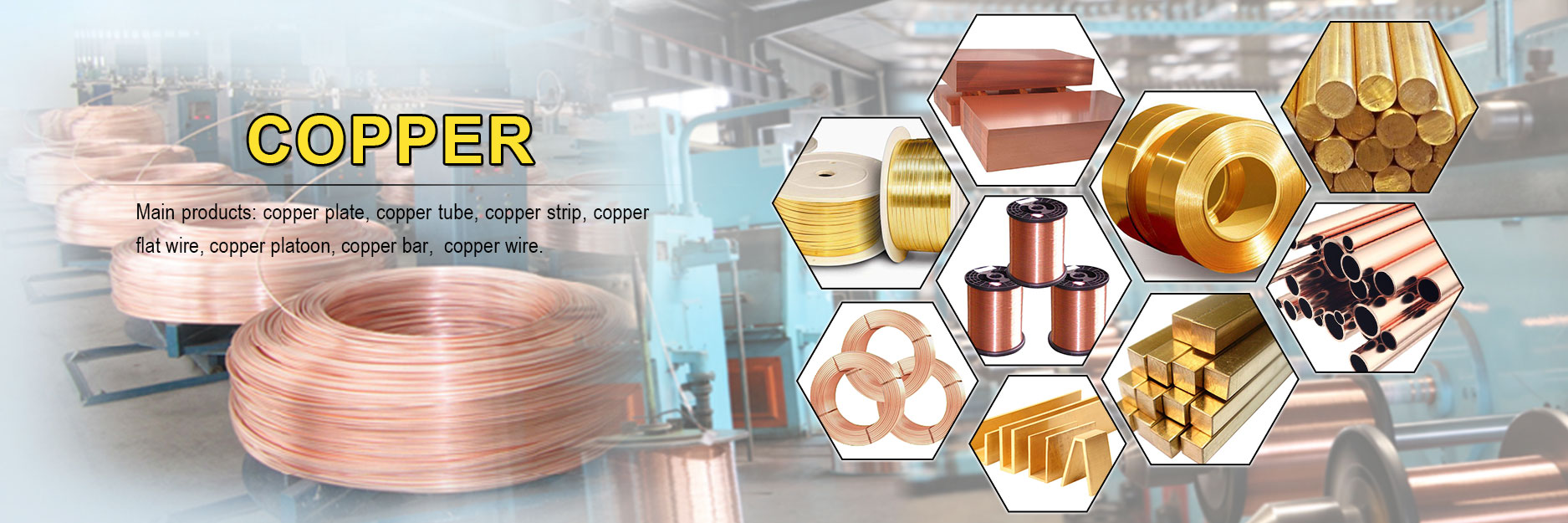

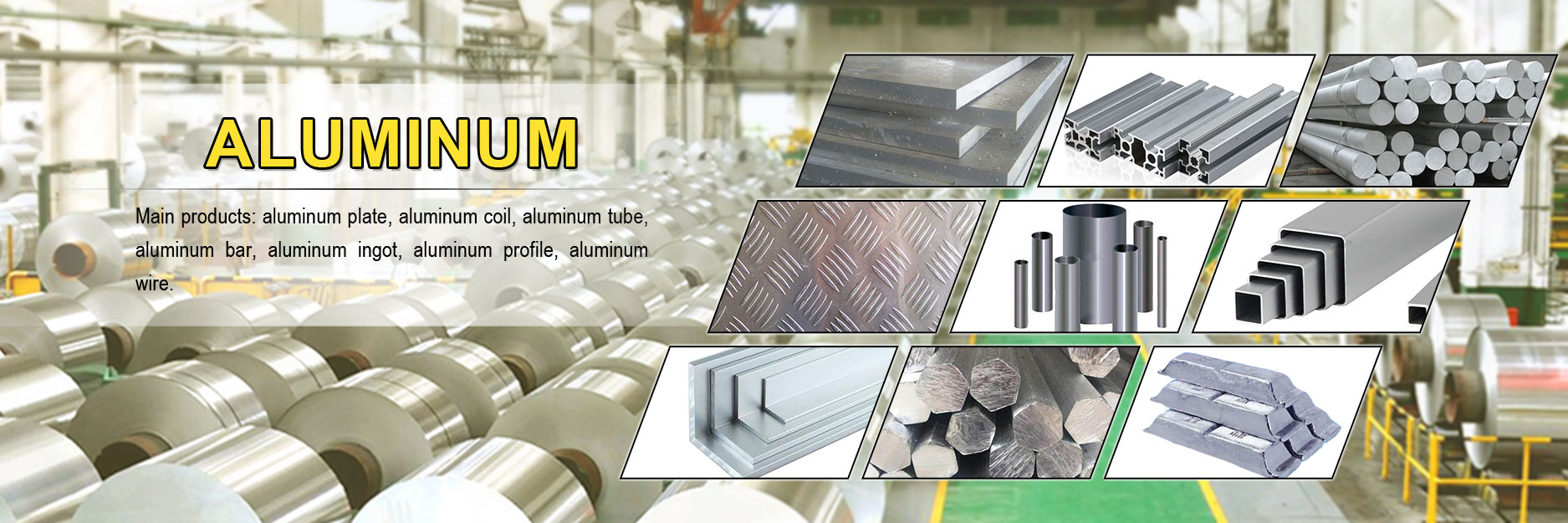

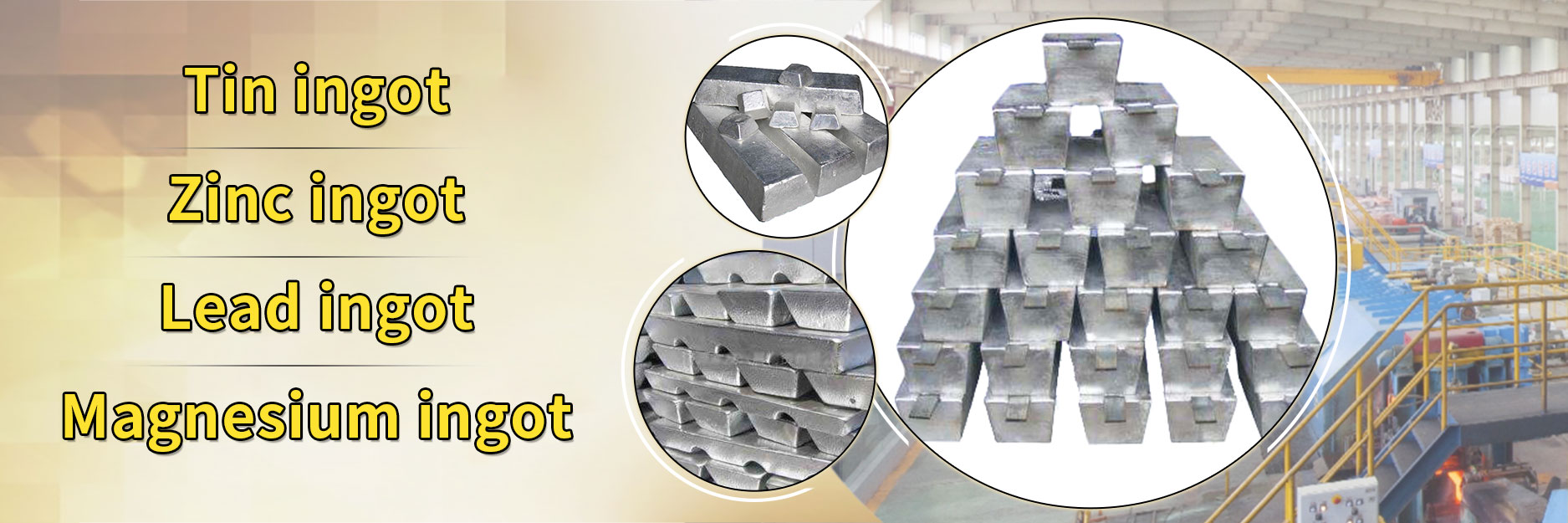

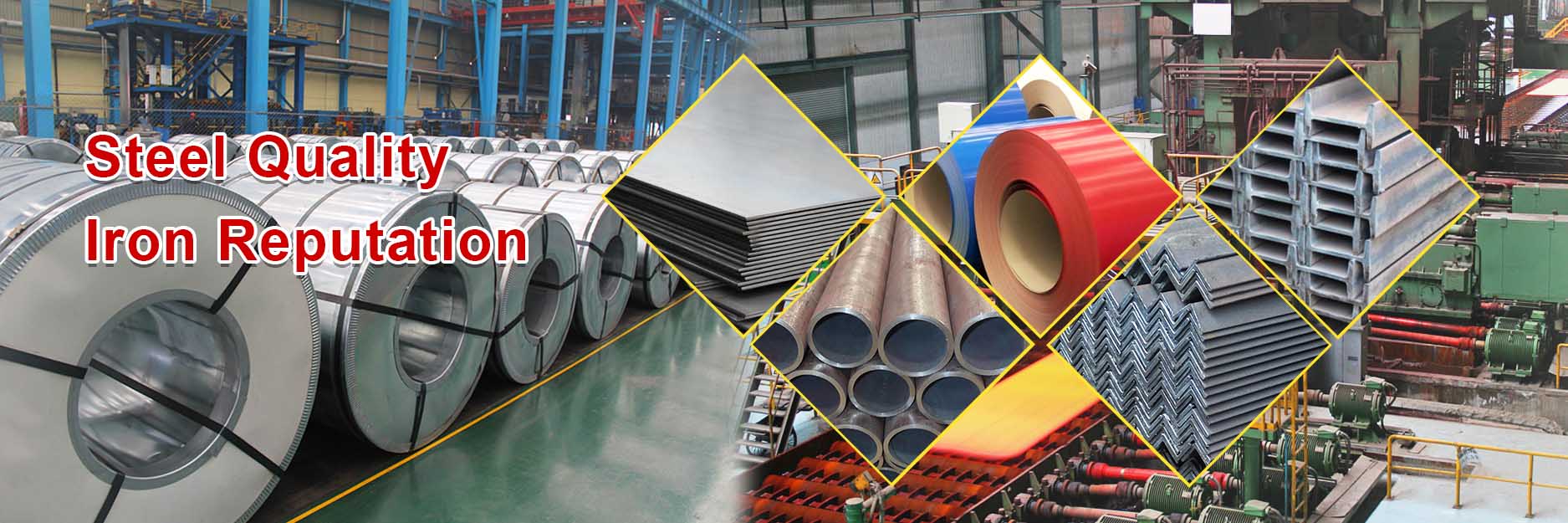

In the metal industry, we have everything you want, one-stop warehousing and processing services.

- Request an order

Welcome to our company

About Us

Wanlutong Metal Material Co., Ltd. is one of the earliest national professional metal manufacturers established in China. After many years of good faith management, the company is a large-scale industrial metal holding company integrating aluminum and aluminum alloy industry, copper and copper alloy industry, zinc, lead, tin, steel, stainless steel and other metal industry logistics. The company has established extensive business cooperation relationships with 142 countries and regions around the world, making important contribution to China’s reform and opening up and new era industrial development..

DOWNLOAD HERE

.

-

Phosphorus copper ingots are high-performance copper alloys enriched with a controlled amount of phosphorus. Known for their exceptional deoxidizing properties, improved strength, and excellent corrosion resistance, these ingots are essential in many metallurgical and industrial applications. Whe...

-

Purple copper ingots, often referring to high-purity copper with a distinctive reddish-purple hue, are a critical raw material in industries that demand excellent thermal and electrical conductivity, corrosion resistance, and structural integrity. These ingots serve as a base material for a wide ...

-

Introduction Phosphorus copper wire, also known as phosphorus-deoxidized copper wire or Cu-DHP (Deoxidized High Phosphorus), is a specialized copper alloy known for its excellent electrical conductivity, weldability, and corrosion resistance. This alloy is widely used in electrical, mechanical, a...

-

Introduction Brass flat wire is a highly adaptable material used across a variety of industries for both functional and decorative purposes. Made from an alloy of copper and zinc, brass flat wire combines strength, malleability, and corrosion resistance with an elegant golden hue. Its flat, recta...