High Quality Aluminum Handle Bar - Tin bronze tube – Wanlutong Detail:

Quick Details

Type:Wanlutong

Application:Water Heater

Specification:OD:2mm~1004mm

Outer Diameter:3mm-500Mm

Grade:QSn8-0.3 /DIN CuSn8/c52100 tin bronze

Thickness:0.2mm-500mm

Length:5.8m

Cu (Min):60%Alloy Or Not:Is Alloy

Ultimate Strength (≥ MPa):205—245

Elongation (≥ %):20–40%

Wall Thickness:0.2mm~200mm

Outside Diameter:2mm~1004mm

Model Number:QSn8-0.3 /DIN CuSn8/c52100 tin bronze

Place of Origin:Qingdao, China (Mainland)

Material:QSn8-0.3 /DIN CuSn8/c52100 tin bronze

Price Term:CIF

Shape:Round Payment:T/T.L/C

Non-standard specifications can be customized

Packaging & Delivery

Packaging Details

wooden case or woven bag

Delivery Time

10-20workdays

we have our own cooperative copper factory,mainly do aluminum bronze and brass,both have sheet,bar,pipe and wire

Standard: GB/T 5231-2001

QSn8-0.3 features and scope of application

QSn8-0.3 aluminum bronze iron, high strength and friction reduction, good corrosion resistance, pressure and good processability in thermal state, can be electric welding and gas welding,stannum bronze can be used as high tin wear-resistant bronze. With high strength, good anti-friction, and excellent corrosion resistance in the atmosphere, fresh water, and seawater, suitable for heat processing and welding.

Chemical composition of QSn8-0.3

Sn:7.0-9.0

P:0.03-0.35

Zn:≤0.20

Ni:≤0.20

Fe:≤0.01

Pb:≤0.05

Cu:REST

Note: the tensile mechanical properties at room temperature of the longitudinal bars

QAl9-4 heat treatment specification: thermal processing temperature 750 ~ 850 °C; annealing temperature 700 ~ 750 °C; quenching temperature 850 °C water; tempering temperature 500 ~ 550 °C.

Description:

bronze with tin as the main alloy element. Tin content is generally between 3 ~ 14%, mainly used to make elastic components and wear-resistant parts. Wrought tin bronze contains no more than 8% tin, sometimes with phosphorus, lead, zinc, etc. Phosphorus is a good deoxidizer and can improve fluidity and wear resistance. Lead in tin bronze can improve machinability and wear resistance, and zinc can improve casting property. The alloy has high mechanical properties, antiwear and corrosion resistance, easy cutting, good brazing and welding properties, low shrinkage coefficient and no magnetism. Wire flame spraying and arc spraying can be used to prepare bronze bushing, shaft sleeve, magnetic resistance elements and other coatings. Size specifications are 1. 6 mm, 2. 3 mm. With high strength, corrosion resistance and excellent casting properties, it has been widely used in various industrial sectors for a long time.

Features:

light weight, good thermal conductivity, high low temperature strength. Often used in the manufacture of copper tubes for heat transfer equipment (eg condensers, etc). It is also used to assemble low temperature pipeline in oxygen making equipment. Copper pipes with small diameters are often used for conveying pressurized liquids (such as lubricating systems, oil pressure systems, etc.) and for measuring pressure pipes used as instruments.

Role:

phosphor bronze has higher corrosion resistance, wear resistance, no sparks during impact. For medium speed, heavy load bearing, working temperature 250 ℃. It has the characteristics of automatic centering, insensitivity to deflection, high uniform bearing capacity, radial load and self-lubricating without maintenance. Tin phosphor bronze is a kind of alloy copper, which has good electrical conductivity and is not easy to heat up, so it is safe and has strong fatigue resistance at the same time.

Chemistry:

| name | basis | mechanical property | |||

| status | tensile strength /MPa | elongation/% | Brinell hardness/MPa | ||

| QSn 4-0.3 | Cu-4Sn-0.3P |

soft hard

|

340 600 |

52 8 |

55~70)×10(160~180)×10 |

| QSn6.5-0.1 | Cu-6.5Sn-0.15P |

soft hard

|

350~450 700~800 |

60~70 7.5~12 |

70~90)×10(160~200)×10 |

| QSn6.5-0.4 | Cu-6.5Sn-0.4P |

soft hard

|

350~450 700~800 |

60~70 7.5~12 |

70~90)×10(160~200)×10 |

| QSn 7-0.2 | Cu-7 Sn-0.2P |

soft hard

|

340 600 |

52 8 |

55~70)×10(160~180)×10 |

| QSn 4-3 | Cu-4Sn-3Zn |

soft hard

|

350 550 |

40 4 |

60×10 160×10 |

| QSn4-4-2.5 | Cu-4Sn-4Zn-2.5Pb |

soft hard

|

300~350 550~650 |

35~45 2~4 |

60×10(160~180)×10 |

| QSn 4-4-4 | Cu-4Sn-4Zn-4Pb |

soft hard

|

300~350 550~650 |

46 2~4 |

62×10(160~180)×10 |

Brand number:

QSn4-3,QSn4-4-2.5,QSn4-4-4。QSn6.5-0.1,QSn6.5-0.4,QSn7-0.2,QSn4-0.3,

Implementation criteria:(GB/T 16866-2006)

Correspondence:

|

China |

Russia |

America |

Britain |

France |

Germany |

Japan |

|

QSn4-3 |

БPOЦ4-3 | |||||

|

QSn4-4-2.5 |

БPOЦ4-4-2.5 | |||||

|

QSn4-4-4 |

БPOЦ4-4-4 |

C54400 |

||||

|

QSn6.5-0.1 |

БPOΦ6.5-0.15 |

PB100 |

||||

|

QSn6.5-0.4 |

БPOΦ6.5-0.4 |

C51900 |

PB103 |

CuSn6P |

CuSn6 |

C5191 |

|

QSn7-0.2 |

БPOΦ7-0.2БPOΦ8-0.3 |

C52100 |

PB104 |

CuSn8 |

C5212 |

|

|

QSn4-0.3 |

БPOΦ4-0.25БPOΦ2-2.25 |

C51100 |

PB101 |

CuSn2 |

C5101 |

Product detail pictures:

Related Product Guide:

All Purpose Copper Tube For Home and Office

5 Steps to Wrap a Window Sill Using Aluminum Coil

High Quality Aluminum Handle Bar - Tin bronze tube – Wanlutong, The product will supply to all over the world, such as: , , ,

-

Factory supplied Aluminum Extrusion Square Tube...

-

Factory made hot-sale Engraved Plate - Lead in...

-

Factory Cheap Copper Mould Tubes Italy - Alumi...

-

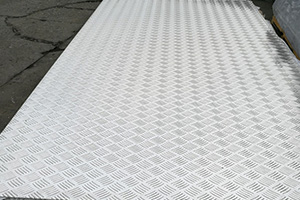

OEM/ODM Factory 5052 Embossed Aluminum Coil - ...

-

Wholesale Price China 6061 T5 Aluminum Extrusio...

-

Popular Design for Square Lapel Pins - Aluminu...