Leading Manufacturer for Copper Coate Tube - Copper line – Wanlutong Detail:

Quick Details

Place of Origin:Qingdao, China (Mainland)

Brand Name:WANLUTONG, WANLUTONG

Model Number:CCA- 491

Type:Bare

Application:conductor

Conductor Material:Copper Clad Aluminum

Conductor Type:Solid

Insulation Material:Bare wire

Name:enameled copper clad aluminum wire cca winding wire

Certification:ISO9001

Material:Copper

Insulation:no

Color:outside copper color

Size:0.12~5.00mm

Packing:Plastic spools

Shipping port:QingdaoPayment term:T/T L/C

Packaging & Delivery

Packaging Details

5″ plastic spool

Stretch film wrapping

Carton

Pallet

According to customer’s request…

Delivery Time

30days copper clad aluminum wire cca wire

Non-standard specifications can be customized

Product Description

Intruduction of the Electric Wire PVC Insulated Single Core H05V-U / H07V-U/ H07V-R wire:

1, The national certification of qualified manufacturers

2, Standard: GB 5023.1, IEC 60227/228, VDE

3, CE, RoHS, ISO ,SGS Certificate

4, Meet European standards and can be customized according to customer requirements

5, OEM, ODM cooperation

Describe

H05V-U / H07V-U are harmonized PVC European single-conductor hook-up wires with a solid bare copper core. Ideal for the internal wiring of appliances, apparatus, switchboards and distributor boards or where a solid core is required. Suitable in dry rooms for fixed and flexible laying. May be used for exposed and embedded conduits. Found in electronic and electrical equipment and switchgear cabinets designed for export to a European country for MRO replacement of European made equipment wire.

The products is suitable for use in power installations, fixed wiring or flexible connections for electrical appliances, Like lighting, electronic equipment, instrument and communication equipment with rated voltage 300/500V, 450/750V, The Operating temperature: Allowing the wire of work for long time should not exceed +70 centigrade.

Used to refer to a telegram . Qing Li Hongzhang Lingxiao ‘ s approach to solving the problem : ” To , for example , to have the Hajj , severance , copper wire , railway . It is necessary to raise the picture ” now refers to a metallic material . It is good in conductivity and good in thermal conductivity . In life , the practical copper wire is used as the conducting wire . The conductivity is good , and it is used in the manufacture of electric wires , cables , brushes , etc .

Good thermal conductivity , commonly used to manufacture magnetic instruments , instruments , such as compass , aviation instrument , etc . , which are required to prevent magnetic interference ;

The pure copper product is made of copper material such as pipe , rod , wire , strip , strip , plate , foil , etc . The pure copper product has two kinds of copper material such as pipe , rod , wire , strip , strip , plate , foil and the like . The pure copper product has two kinds of tensile strength : ≥ 315 elongation : ≥ 30 other wire outside the wire rod : diameter : 2.0 ~ 4.0 material : T1 , T2 , T3 . T8 , C1100 , C1100 , C1020 , C1201 , C1220 , C1271 , C2100 , C1201 , C2300 , C2400 , C2600 , C2680 , C2700 , C2720 , C2800 , C2801 , H62 , H62 , H63 , H65 , H68 , H70 , H80 , H85 , H90 , H96 , etc . Hardness : O , 1 / 2H , 3 / 4H , H , EH , SH , etc . It has good conductivity , thermal conductivity , corrosion resistance and processability . It can be welded and soldered . It has less conductive and thermal conductivity , and trace oxygen has little effect on conductivity , heat conduction and processing . It is not suitable for processing ( annealing , welding , etc . ) in reducing atmosphere at high temperature ( e.g . & gt ; 370.degree . C . ) .

1. With composite characteristics: the bimetallic wire combines different beneficial properties in a single wire. Copper Clad Aluminm CCA/CCAM wire integrates the beneficial properties of the wonderful conductivity of copper and the light-weight of aluminum; Tinned CCA/CCAM wire is good at anti-vulcanization.

2. With wonderful plasticity and easy to process further: CCA/CCAM wire can be done in the same way as with copper wire. CCA/CCAM wire is easy to be processed to fine wire or flat wire, and CCA/CCAM wire can be tinned.

3. Economical effect: the density of CCA is about 32~40% of the copper, its length is 2.45~3.00 times of copper in same weight and diameter. All of these contribute to reduce production cost for cable manufacturers.

4. Social and environmental effect: It is helpful to save copper resource by using copper-clad wire. The finished cable will be easy to transport and install because of light weight, and there is no pollution discharged during the production with clad-welding technique.

Characteristic:

Now all the wires on the market are copper wires, which are far more than aluminum wires. Why is the market share of copper wires so high? the following is about the characteristics of using copper cores. 1, high strength: the allowable stress at room temperature, copper is higher than aluminum by 7 / 28 respectively. Especially the stress at high temperature, the difference between the two is very far. 2, anti-fatigue: aluminum is easy to break after repeated bending, copper is not easy. In terms of elastic index, copper is also about 1.7 ~ 1.8 times higher than aluminum. 3, good stability, corrosion resistance: copper core oxidation resistance, corrosion resistance, while aluminum core is vulnerable to oxidation and corrosion. 4, large current: because of the low resistivity, the copper core wire with the same section is about 30% higher than the aluminum core wire. 5, low resistivity: the resistivity of aluminum core wire is about 1.68 times higher than that of copper core wire. 6, good ductility: the elongation rate of copper alloy is 20% 40%, that of electrical copper is more than 30%, and that of aluminum alloy is only 18%. 7. Construction convenience: 1 copper core is flexible, the allowable bend radius is small, so it is convenient to turn around, it is easy to wear pipe to resist fatigue of copper core, and repeated bending is not easy to break, so the convenient connection of copper core is higher than the mechanical strength of copper core. It can bear large mechanical tension, bring great convenience to construction laying, and also create conditions for mechanized construction. 8, low heating temperature: at the same current, the same section of copper wires have much less heat than aluminum wires, making it safer to operate. Low voltage loss: because of the low resistivity of the copper core wire, the same cross section flow through the same current. The voltage drop of copper core wire is small. Anti-oxidation, corrosion resistance: copper core wire connector performance stability, not due to oxidation accident. The joint instability of aluminum core wire often causes the contact resistance to increase and heat up due to oxidation. As a result, the accident rate is much larger than the copper core wire. 11, low energy consumption: because of the low resistivity of copper, copper wires have lower power loss than aluminum wires, which is obvious. This is conducive to increasing the utilization rate of electricity generation and protecting the environment.

act on:

The choke coil is a common mode interference suppression device with ferrite as the core. It is symmetrically wound on the same ferrite ring core by two coils of the same size and the same turns, forming a four-terminal device. The large inductance of common mode signal is inhibited, but the leakage inductance of differential mode signal is very small. The choke coil can effectively suppress common-mode interference (such as lightning interference) in balanced line, but has no effect on the normal transmission of differential mode signal. The choke coil should meet the following requirements: 1) the wires wound on the coil core should be insulated each other to ensure that there is no breakdown and short circuit between turns of the coil under the action of instantaneous overvoltage. 2) when the coil flows through the instantaneous high current, the core does not appear saturated. 3) the magnetic core in the coil should be insulated from the coil to prevent the breakdown between the two under the action of instantaneous overvoltage. 4) the coil should be wound in a single layer as much as possible, which can reduce the parasitic capacitance of the coil and enhance the ability of the coil to grant the instantaneous overvoltage.

Specifications:

1. Copper wire specifications are as follows

0.07mm;0.10mm;0.15mm;0.20mm;0.25mm;0.30mm;0.05mm。

2.material quality:

T1、T2、T3、C1100、C5111、C5101、C5191、C5210、TU1、C1020、C1201、C1220、C1271、C2100、C2200、C2300、C2400、C2600、C2680、C2700、C2720、C2800、C2801、H62、H62、H63、H65、H68、H70、H80、H85、H90、H96…..

specifications:Line diameter:0.01-15.0mm。hardness:O、1/2H、3/4H、H、EH、SH……

3、The diameter of BV 2.5 square millimeter wire is 1.76 mm 1.75 mm 1.74 mm 1.73 mm 1.72 mm as long as it is less than or equal to 1.9 mm, so long as the resistance value is qualified, it is the national standard.

the name of a shop:

T2,TU1,TU2,TP1,TP2,H59,H62,H65,H68,H70,H80,H85,H90,H96。

Brass line correspondence:

|

China |

international standard |

America |

Japan |

Britain |

Germany |

|

H59 |

CuZn41 |

C28000 |

C2800 |

CZ109 |

CuZn39 |

|

H62 |

CuZn38 |

C27400 |

C2740 |

CuZn40 |

|

|

H65 |

CuZn35 |

C26800 |

C2680 |

CZ107 |

CuZn36 |

|

H68 |

CuZn32 |

C26000 |

C2600 |

CuZn33 |

|

|

H70 |

CuZn30 |

C26000 |

C2600 |

CZ106 |

CuZn30 |

|

H80 |

CuZn20 |

C24000 |

C2400 |

CZ103 |

CuZn20 |

|

H85 |

CuZn15 |

C23000 |

C2300 |

CZ102 |

CuZn15 |

|

H90 |

C22000 |

C2200 |

CZ101 |

CuZn10 |

|

|

H96 |

CuZn4 |

C21000 |

C2100 |

CZ125 |

CuZn5 |

Corresponding relation of purple copper wire

|

China |

international standard |

America |

Japan |

Britain |

Germany |

|

T2 |

Cu-RTP |

C11000 |

C1100 |

C101 |

R-Cu57 |

|

TU1 |

Cu-OF |

C10200 |

C1020 |

C110 |

OF-Cu |

|

TU2 |

Cu-OF |

C10300 |

C1020 |

C103 |

OF-Cu |

|

TP1 |

Cu-DLP |

C12000 |

C1201 |

SW-Cu |

|

|

TP2 |

Cu-DHP |

C12200 |

C1220 |

C106 |

SF-Cu |

The corresponding relation of Phosphorus-Copper Wire

|

China |

Russia |

America |

Britain |

France |

Germany |

Japan |

|

QSn4-3 |

БPOЦ4-3 | |||||

|

QSn4-4-2.5 |

БPOЦ4-4-2.5 | |||||

|

QSn4-4-4 |

БPOЦ4-4-4 |

C54400 |

||||

|

QSn6.5-0.1 |

БPOΦ6.5-0.15 |

PB100 |

||||

|

QSn6.5-0.4 |

БPOΦ6.5-0.4 |

C51900 |

PB103 |

CuSn6P |

CuSn6 |

C5191 |

|

QSn7-0.2 |

БPOΦ7-0.2БPOΦ8-0.3 |

C52100 |

PB104 |

CuSn8 |

C5212 |

|

|

QSn4-0.3 |

БPOΦ4-0.25БPOΦ2-2.25 |

C51100 |

PB101 |

CuSn2 |

C5101 |

Product detail pictures:

Related Product Guide:

Aluminum Coil: An Earth-Friendly Industrial Material

All Purpose Copper Tube For Home and Office

Leading Manufacturer for Copper Coate Tube - Copper line – Wanlutong, The product will supply to all over the world, such as: , , ,

-

Cheapest Factory Tinned Coated Copper Bus Bar -...

-

Newly Arrival Aluminum Bottle Opener - Color a...

-

One of Hottest for S45c Round Bar - Purple-red...

-

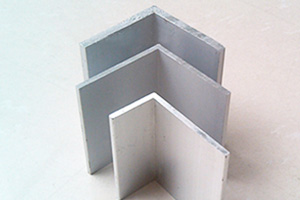

Hot-selling Groove Cutter Bar - Unequal angle ...

-

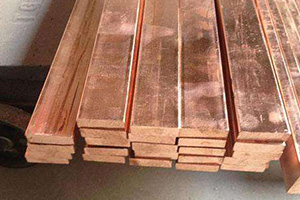

IOS Certificate Copper Flat Bar - bare copper ...

-

Big Discount shaped Metal Craft - Oxygen-free ...