Wholesale Price China Nickel Plated Copper Tube - Aluminum alloy plate – Wanlutong Detail:

Brand Name:wanlutong

Place of Origin:Shandong, China (Mainland)

Product name:Aluminum alloy plate

Temper:O-H112

Type:Plate

Model Number:1 Series-9 Series

Application:Construction,decoration,Pressure vessel;Marine; Storage Tank etc

Thickness:0.1mm-500mm

Width:20mm-3000mm

Surface Treatment:mill finish

Alloy Or Not:Is Alloy

standard:GB/T 3190-2008, JIS, EN, ASTM

Color:Silver, or as per customer’s requirement

Quality Control:ISO 9001:2008,SGS,QC

Non-standard specifications can be customized.

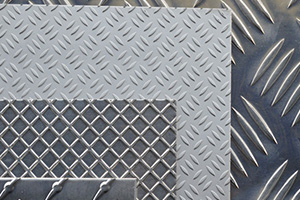

ALUMINUM ALLOY PLATE

Description:

Aluminum alloy plate is an industrial building material, according to the different materials used in various industries, according to the surface treatment can be divided into non-painting products and paint products two categories. The industries used include aircraft structure, rivets, missile components, truck hubs, packaging and adiabatic aluminum foil, heat exchangers, spacers, fins, and wing beams.

Aluminium alloy is divided into

1 series – 9 series

1 series:

Features: aluminum 99.00%, good conductivity, good corrosion resistance, good welding performance, low strength, non-heat treatment.

Application range: high purity aluminum (containing 99.9% aluminum content) is mainly used for scientific test, chemical industry and special purpose.

2 series:

Features: aluminum alloy with copper as the main element, manganese, magnesium, lead and bismuth are added for cutting. In the process of smelting, safety protection (harmful gas will be produced). The 2014 alloy is of high strength and aviation industry. The 2017 alloy is a bit lower than the 2014 alloy, but it is easier to process. It can be strengthened by heat treatment in 2014.

Faults: the tendency of intergranular corrosion is serious.

Application range: aviation industry (2014 alloy), screw (2011 alloy) and use of high temperature industry (2017 alloy).

3 series:

Features: aluminum alloy with manganese as the main alloy, non-heat treatment, good corrosion resistance and good welding performance. Good plasticity. (close to super alloy).

Disadvantages: low strength, but can be strengthened by cold working hardening. It is easy to produce coarse grain when annealing.

Range of application: seamless tube (3003 alloy) and can (3004 alloy) used on aircraft.

4 series: mainly silicon, not commonly used. Some of the 4 series are heat treatable, but some of the 4 alloys are not heat-treatable.

5 series:

Features: mainly magnesium. Good endurance, good welding performance, good fatigue strength, non-heat treatment hardening, only cold processing to improve strength.

Application scope: the handle of the lawn mower, the fuel tank catheter, the body armor. Generally, the upper end of the shoe rack is 6 or 7.

6 series:

Features: magnesium and silicon mainly. Mg2Si is the main strengthening phase, currently the most widely used alloy. The maximum number of use is 6082, 6082, 6160, 6125, 6262, 6060, 6005, 6463. The strength of 6063, 6060 and 6463 is relatively low in 6 series. The strength of 6262, 6005, 6082 and 6061 is relatively high in 6 series. The rack at the middle of the cyclone is 6061.

Characteristics: moderate strength, good corrosion resistance, good welding property, good process performance (easy extrusion forming), good oxidation coloring performance.

Application scope: power tools (e.g., car luggage rack, door, window, body, heat sink, compartment shell)

7 series:

Features: mainly contains zinc. Also belongs to aviation series, is aluminum magnesium zinc copper alloy, can heat treatment alloy, belong to super hard aluminum alloy, have good wear resistance. The 7075 aluminum plate is eliminated by stress. After processing, it will not be deformed and warped. All the super-thick 7075 aluminum plates are detected by ultrasonic wave, which can guarantee the non-sand eye and impurities. The high thermal conductivity of 7075 aluminum plate can shorten the molding time and improve working efficiency. The main characteristic is hardness, 7075 is high hardness, high strength aluminum alloy, often used in manufacturing aircraft.

8 series:

More commonly used for 8011 aluminum plate, belong to other series. The aluminum plate which is the main function of the bottle cap is also applied to the radiators, most of which are aluminum foil. In the business market is not very common series.

9 series:

9 department belongs to the alternate series, technology is so advanced, in response to contain other alloying elements of aluminium plate, international federation of aluminum belt, showed that 9 XXX series for standby, waiting for another new varieties appear to fill the blank of the 9 series of XXX.

Features:

Aluminum alloy density is low, but the intensity is high, close to or more than high-quality steel, plastic, can be processed into various profiles, with excellent electrical conductivity, thermal conductivity and corrosion resistance, widely used on industry, usage is second only to the steel.

Uses

The industries used include aircraft structure, rivets, missile components, truck hubs, packaging and adiabatic aluminum foil, heat exchangers, spacers, fins, and wing beams. Lighting lighting, solar reflection, building exterior and interior decoration, ceiling, metope, furniture, cabinets, elevators, signs, nameplate, luggage, automotive interior and exterior decoration, interior decoration, such as picture frames, household appliances, refrigerators, microwave ovens, audio equipment, such as aerospace and military aspects, such as China’s large aircraft manufacturing, the shenzhou spacecraft series, satellites, etc., machinery parts processing, mold manufacturing, chemical/insulation pipeline coating, high quality planking.

Executive standard:

GB/ t3880-2006 《general industrial aluminum and aluminum alloy plate, strip》

GB 5237-2004《aluminum alloy building profile》

Chemical composition:

Al: margin.

Si: 0.25.

Copper Cu: 0.10.

Magnesium Mg: 2.2 ~ 2.8.

Zinc Zn: 0.10.

Mn: 0.10.

Cr: 0.15 ~ 0.35.

Fe: 0.4 0.

Correspondence:

|

China |

Japan |

America |

International Standard |

Europe |

|

1080A |

- |

- |

AW-1080A AW-Al99.8 |

EN AW-1080A EN AW-Al99.8(A) |

|

1070A |

- |

- |

AW-1070 AW-Al99.7 |

EN AW-1070A EN AW-Al99.7 |

|

1060 |

1060 (JIS H4180:1990) |

1060 |

- |

EN AW-1060 EN AW-Al99.6 |

|

1100 |

1100 |

1100 |

AW-1100 AW-Al99.0Cu |

EN AW-1100 EN AW-Al99.0Cu |

|

1200 |

1200 |

1200 |

AW-1200 AW-Al199.0 |

EN AW-1200 EN AW-Al99.0 |

|

2014 |

2014 |

2014 |

AW-2014 AW-AlCu4SiMg |

EN AW-2014 EN AW-AlCu4SiMg |

|

2014A |

- |

- |

AW-2014A AW-AlCu4SiMg |

EN AW-2014A ENAW-AlCuSiMg(A) |

|

2017 |

2017 |

2017 |

AW-2017 AW-AlCu4MgSi |

- |

|

2017A |

- |

- |

AW-2017A AW-AlCu4MgSi |

EN AW-2017A ENAW-AlCu4MgSi (A) |

|

3004 |

3004 |

3004 |

AW-3004 AW-AlMn1Mg1 |

EN AW-3004 EN AW-AlMn1Mg1 |

|

3104 |

3104 |

3104 |

- |

EN AW-3104 EN AW-AlMn1Mg1Cu |

|

3005 |

3005 |

3005 |

AW-3005 AW-AlMn1Mg0.5 |

EN AW-3005 EN AW-AlMn1Mg0.5 |

|

3105 |

3105 |

3105 |

AW-3105 AW-AlMn0.5-Mg0.5 |

EN AW-3105 EN AW-AlMn0.5Mg0.5 |

|

5050 |

- |

5050 |

AW-5050 AW-AlMg105 |

EN AW-5050 EN AW-AlMg1.5(C) |

|

5052 |

5052 |

5052 |

AW-5052 AW-AlMg2.5 |

EN AW-5052 EN AW-AlMg2.5 |

|

5454 |

5454 |

5454 |

AW-5454 AW-AlMg3Mn |

EN AW-5454 EN AW-AlMg3Mn |

|

5754 |

- |

5754 |

AW-5754 AW-AlMg3 |

EN AW-5754 EN AW-AlMg3 |

|

5082 |

5082 |

5082 |

AW-5082 AW-AlMg4.5 |

EN AW-5082 EN AW-AlMg4.5 |

|

5182 |

5182 |

5182 |

AW-5182 AW-AlMg4.5-Mn0.4 |

EN AW-5182 ENAW-AlMg4.5Mn0.4 |

|

5083 |

5083 |

5083 |

AW-5083 AW-AlMg4.5-Mn0.7 |

EN AW-5083 ENAW-AlMg4.5Mn0.7 |

|

5086 |

5086 |

5086 |

AW-5086 AW-AlMg4 |

EN AW-5086 EN AW-AlMg4 |

|

6061 |

6061 |

6061 |

AW-6061 AW-AlMg1SiCu |

EN AW-6061 EN AW-AlMg1SiCu |

|

6063 |

6063 |

6063 |

AW-6063 AW-AlMg0.7Si |

EN AW-6063 EN AW-AlMg0.7Si |

|

6082 |

- |

- |

AW-6082 AW-AlSiMgMn |

EN AW-6082 EN AW-AlSi1MgMn |

|

7020 |

- |

- |

AW-7020 AW-AlZn4.5Mg1 |

EN AW-7020 EN AW-AlZn4.5Mg1 |

|

7021 |

- |

7021 |

- |

EN AW-7021 EN AW-AlZn4.5Mg1.5 |

|

7075 |

7075 |

7075 |

AW-7075 AW-AlZn5.5-MgCu |

EN AW-7075 EN AW-AlZn5.5MgCu |

|

7475 |

- |

- |

AW-7475 AW-AlZn5.5-MgCu (A) |

EN AW-7475 ENAW-AlZn5.5-MgCu(A) |

|

8079 |

8079 |

8079 |

- |

EN AW-8079 EN AW-AlFe1Si |

Product detail pictures:

Related Product Guide:

Copper Tubing Coils

Aluminum Coil: An Earth-Friendly Industrial Material

Wholesale Price China Nickel Plated Copper Tube - Aluminum alloy plate – Wanlutong, The product will supply to all over the world, such as: , , ,