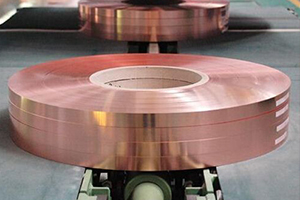

Wholesale Price Copper Water Tube Pipe - Purple-red copper strip – Wanlutong Detail:

Quick Details

Application: Electronic Material:CuCr1Zr

Thickness:0.035-300mm Width:5-2000mm Customer’s Request

Grade:Copper Alloy Cu (Min):98.5%

Alloy Or Not:Non-alloy Model Number:C18150

Brand Name:Wanlutong Place of Origin:Qingdao, China (Mainland)

Product Name:C18150 copper strip Surface:Polished

Color:Red Purple Hardness:1/2Hard

PRICE TERM:CIF CFR FOB Ex-Work Certificate:SGS

Standard:JIS ASTM DIN EN ISO Shipment:Air Sea

Package:Wooden Sample:Avaliable

Port:Qingdao,China Payment:T/T,L/C

Non-standard specifications can be customized

Packaging & Delivery

Packaging Details

Use rust-proof paper packaging inside and outside use plastic bags, wooden box for C18150 copper strip..

Delivery Time

in 30 days

Description:

Pure copper is rose-red metal, the surface of copper oxide film is purple, so industrial pure copper is often called copper or electrolytic copper. 99-99.9% of pure copper can be obtained by pyrolysis, and the purity of copper can reach 99.95-99.99kum by electrolysis. The density is 8 ~ 9 g / cm ~ 3 and the melting point is 1083 °C. Good electrical conductivity of pure copper, used in large quantities in the manufacture of wires, cables, brushes, etc.; good thermal conductivity, often used in the manufacture of magnetic instruments, such as compasses, aeronautical instruments, etc.; excellent plasticity, easy hot pressing and cold pressure processing, Can be made into tubes, rods, wires, strips, strips, plates, foil and other copper. Pure copper products have two kinds of smelting products and processed products. Complete specifications, price concessions, good packaging, pure copper, good straightness, large inventory, can provide material proof and SGS report.

Red copper is relatively pure copper. It fully shows the ductility, electrical conductivity and corrosion resistance of copper, among which ductility is an important feature of copper ornaments. Copper has a high melting point and is not easy to cast, and good ductility makes up for this shortcoming, so it can be easily processed into various modeling patterns. The dark red metallic gloss makes it the most commonly used material in copper ornaments because of its calm and noble quality. High purity, fine tissue and very low oxygen content. No porosity, trachoma, loose, excellent electrical conductivity, high surface accuracy of electroetching mould, heat treatment technology, no direction of electrode, suitable for fine beating, good thermoelectric, processability, ductility, Corrosion resistance and weathering. Good electrical conductivity, heat conduction, corrosion resistance and processing performance, soldering and brazing.

Purpose:

Copper is used more widely than pure iron, 50% of copper is electrolyzed to pure copper each year, used in electrical industry. The copper in question really needs to be very pure and contains more than 99.95% copper. A very small amount of impurities, especially phosphorus, arsenic, aluminum and so on, will greatly reduce the conductivity of copper. Oxygen in copper (which is easy to be mixed with a small amount of oxygen in copper smelting) has a great influence on conductivity. Copper used in electrical industry must be oxygen free copper. In addition, lead, antimony, bismuth and other impurities will make copper crystal can not be combined, resulting in hot brittle, will also affect the processing of pure copper. This kind of pure copper with high purity is usually refined by electrolysis: using pure copper as anode, pure copper as cathode and copper sulfate solution as electrolyte. When the current passes, the impure copper on the anode gradually melts and the pure copper is precipitated on the cathode. Copper so refined; purity up to 99.99. Red copper is a kind of copper which is relatively pure, which can be considered as pure copper. Its electrical conductivity and plasticity are better, but its strength and hardness are worse. High purity, fine tissue and very low oxygen content. No porosity, trachoma, loose, excellent electrical conductivity, high surface accuracy of electroetching mould, heat treatment technology, no direction of electrode, suitable for fine beating, good thermoelectric, processability, ductility, Corrosion resistance and weathering. Good electrical conductivity, heat conduction, corrosion resistance and processing performance, soldering and brazing.

Characteristics:

Good electrical conductivity. Heat conduction. Corrosion resistance and processing properties, can be welded and fiber welding. Contains reduced conductivity. Thermal conductivity of less impurities, trace oxygen conductive. The thermal conductivity and processing properties have little influence, but it is easy to cause “hydrogen sickness”, so it is not suitable for processing (annealing) in the reductive atmosphere of high temperature (such as > 370 °). Welding, etc.) and use

Chemical constituents:

Cu+Ag: 99.90 Bi: 0.001 Sb: 0.002 As: 0.002 Fe: 0.005

Pb: 0.005 S: 0.005

Mechanical properties:

Tensile strength: Rm / MPa) ≥ 295 Rockwell hardness (HRF) ≥ 65% elongation) ≥ 3

Specifications: Thickness: 0.1-3.0mm;Width: 30-1000mm。

Brand number: T2 TU1 TU2 TP1 TP2

The corresponding relation of copper belt is:

|

China |

International standards |

America |

Japan |

Britain | Germany |

|

T2 |

Cu-RTP |

C11000 |

C1100 |

C101 |

R-Cu57 |

|

TU1 |

Cu-OF |

C10200 |

C1020 |

C110 |

OF-Cu |

|

TU2 |

Cu-OF |

C10300 |

C1020 |

C103 |

OF-Cu |

|

TP1 |

Cu-DLP |

C12000 |

C1201 |

SW-Cu |

|

|

TP2 |

Cu-DHP |

C12200 |

C1220 |

C106 |

SF-Cu |

Product detail pictures:

Related Product Guide:

The Myriad Benefits of Aluminum Coil

Aluminum Coil: An Earth-Friendly Industrial Material

Wholesale Price Copper Water Tube Pipe - Purple-red copper strip – Wanlutong, The product will supply to all over the world, such as: , , ,