Introduction Can you distinguish aluminum, primary aluminum, electrolytic aluminum, aluminum ingot and alumina?

Introduction Can you distinguish aluminum, primary aluminum, electrolytic aluminum, aluminum ingot and alumina?

Briefly introduce aluminum, primary aluminum, electrolytic aluminum, aluminum ingot, aluminum oxide and the difference between them. If you are interested, please read down!

Electrolytic aluminum is a method of smelting metallic aluminum. Usually, alumina is decomposed into metallic aluminum by high current in an electrolytic cell.

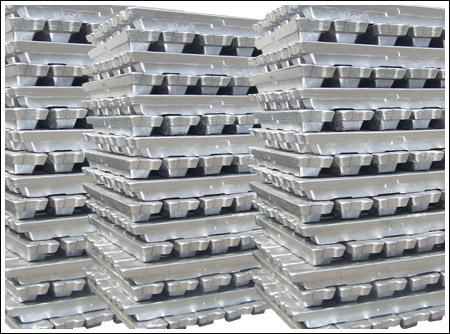

Aluminum ingots are divided into high-purity aluminum ingots, aluminum alloy ingots and aluminum ingots remelted according to their composition. According to its shape and size, it can be divided into round ingots, slab ingots, bar ingots, T-shaped ingots and so on.

Aluminum is a silver-white metal, ranking third after oxygen and silicon in the earth’s crust. Aluminum is called a light metal because of its low density. Aluminum is a non-ferrous metal with high output and wide application, second only to steel in the world. The density of aluminum is about 1/3 of that of steel and copper. Because aluminum is made of lightweight materials, it is often used in manufacturing, trains, subways, cars, airplanes, ships, rockets, and other land, sea and air transportation vehicles to reduce self-weight and increase loading capacity. Similarly, aluminum also plays an important role in military products.

Alumina, also known as alumina, is a white powder. Primary aluminum is liquid aluminum extracted during electrolysis and has not been subjected to precipitation treatment. In the cast aluminum ingot model, primary aluminum can be transformed into an aluminum ingot through cooling treatment. Therefore, alumina is the raw material of molten aluminum, electrolytic aluminum is the process, primary aluminum is the molten aluminum in the electrolysis process, and aluminum ingots are aluminum products that can finally be sold on the market.

Electrolytic aluminum is aluminum obtained by electrolysis. The modern electrolytic aluminum industry uses cryolite-alumina molten salt electrolysis. Molten cryolite is the solvent, alumina is the solute, carbon body is the anode, and molten aluminum is the cathode. After applying a strong direct current, the two poles in the electrolytic cell undergo electrochemical reactions at 950 ~ 970 for electrolysis.

Industrial aluminum ingot: The raw material in our daily industry is called aluminum ingot according to the national standard (GB/T 1196-2008), but everyone is used to calling it “for remelting”. It is produced by electrolysis of alumina-cryolite. After aluminum ingots enter industrial applications, there are two types: cast aluminum alloys and deformed aluminum alloys. Cast aluminum and aluminum alloys are castings produced by casting methods.

Deformed aluminum and aluminum alloys are aluminum processed products produced by pressure processing methods: plates, strips, foils, tubes, rods, molds, wires, and forgings. According to the national standard, “remelting use” is divided into 8 grades according to chemical composition, namely aluminum 99.90, aluminum 99.85, aluminum 99.70, aluminum 99.60, aluminum 99.50, aluminum 99.00, aluminum 99.7E, aluminum 99.6E” (Note: after aluminum The figure is aluminum content). Some people call it “A00″ aluminum, which is actually 99.7% pure aluminum. It is called “standard aluminum” in the London market. As we all know, China’s technical standards originated from the former Soviet Union in the 1950s. , “A00″ is the Russian brand in the Soviet national standard, “A” is the Russian letter, not the English “A”, nor the Chinese pinyin “A”. If it meets the international standards, it is called “standard aluminum”. Accurate. Standard aluminum is aluminum ingot, containing 99.7% aluminum, registered in the London market. Alumina (AlO) is a high-hardness compound with a melting point of 2054 and a boiling point of 2980. It is an ionic crystal that can be ionized at high temperatures It is usually used to make refractory materials. Industrial alumina is made of bauxite (Al2O 33H2O) and diaspore. For alumina with high purity requirements, it is generally prepared by chemical methods.

More details Link: https://www.wanmetal.com/

Reference source: Internet

Disclaimer: The information contained in this article is for reference only, not as a direct decision-making suggestion. If you do not intend to infringe your legal rights, please contact us in time.

Post time: Sep-02-2021