-

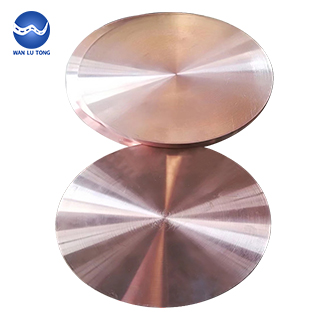

Notes on oxygen free copper casting

Oxygen free copper refers to pure copper that does not contain oxygen or any deoxidizer residue. In the production and production of anaerobic copper rod, processed anaerobic copper is used as the raw material for production and casting. The quality of oxygen free copper rod made of good quality ...Read more -

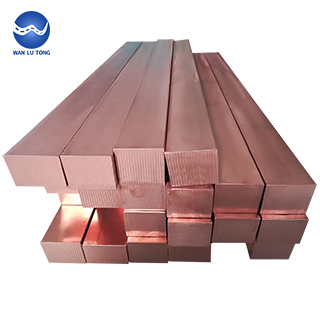

Performance advantages of chrome zirconium copper electrodes

The excellent thermal conductivity of chrome zirconium copper electrode is about 3~4 times better than that of die steel. This feature ensures rapid and uniform cooling of plastic products, reduces deformation of products, unclear shape details and similar defects, and significantly shorens the p...Read more -

Key points of aluminum bronze semi – continuous casting process

Aluminum bronze has the casting properties of strong suction, easy oxidation slag, large solidification shrinkage, poor thermal conductivity, and poor casting performance. Before casting, tin bronze manufacturers used a mixture of some alkali earth metal compounds, such as Na₃AlF₆ and NaF, as a s...Read more -

The strengthening method of chrome zirconium copper

Chrome zirconium copper is a kind of metal material, mainly used in the welding of machinery manufacturing industry. Chromium zirconium copper can be strengthened in the following ways. 1. Deformation strengthening The mechanism of cold deformation strengthening of chrome zirconium copper is that...Read more -

Treatment of chrome zirconium copper after oxidation

Chrome zirconium copper is mainly used for welding in the machinery manufacturing industry, where mechanical and physical properties can be obtained. When this material is used as a general resistance welding, chrome zirconium copper is oxidized and treated in the following ways. 1. Vinegar soaki...Read more -

Classification of oxygen free copper

Oxygen free copper according to oxygen and impurity content, anoxic copper is divided into No. 1 and No. 2 anoxic copper. No. 1 oxygen free copper purity reaches 99.97%, oxygen content is not more than 0.003%, the total impurity content is not more than 0.03%; The purity of No. 2 oxygen-free copp...Read more -

Several factors affecting zinc alloy cutting

With the continuous development of manufacturing technology, a variety of new materials have been developed and widely used. Many of these new materials are difficult to process, such as zinc alloy and composite materials. On the one hand, it greatly improves the product performance, on the other...Read more -

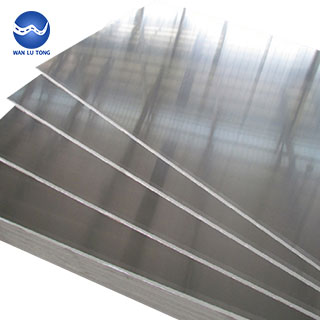

Characteristics and applications of industrial aluminum profiles

As a kind of metal with good plasticity, industrial aluminum profiles have important applications in various aspects of industrial production. Even in the plastic steel doors and Windows industry, aluminum alloy doors with insulation designs are also used in the plastic steel field. Set up indust...Read more -

Methods to improve the coating quality of aluminum alloy plate

The coating room should be kept clean, with dustproof, insect proof and certain ventilation performance, so as to ensure that the surface quality of aluminum alloy plate coating is not polluted. At the same time, the process conditions should be changed in time due to temperature changes. Coating...Read more -

Explanation of the confusion about magnesium alloy

The problem of whether magnesium alloy can be exposed to water is determined according to the use. When encountering water, magnesium alloys will show signs of corrosion. Some may not like the corrosion, while some corrosion types like the corrosion of this material very much. This material will ...Read more -

The discrimination of high quality aluminum alloy plate

Wrap the aluminum alloy plate in plastic and then fold it away. Insulating aluminum skins should not be placed on the roofs of workshops and warehouses where rainwater leaks to ensure that they are kept in a dry environment. Normally, the aluminum skin will be packed in a waterproof package with ...Read more -

Main factors of forgeability of magnesium alloys

The malleability of magnesium alloys mainly depends on three factors: alloy solid melting temperature, deformation rate and grain size, therefore, the study of magnesium alloy forging are mainly concentrated in, how to reasonably control temperature range, appropriate selection of deformation rat...Read more