-

Aluminum plate processing plant tells you what factors affect the color difference of the aluminum plate surface

If the actual effect of aluminum double plate color can not exceed the estimated actual effect, it will cause great harm to its use. In manufacturing, what are the color differences affecting the surface of aluminum plate? Surface color elements of aluminum plate: 1. Dyeing solution temperature. ...Read more -

Pattern aluminum plate common six kinds of classification

Aluminum embossed plate is a common aluminum plate, which is also used in decoration and life. The classification of pattern aluminum plate has made the following summary for us, hoping to help you understand the product. 1, the compass aluminum alloy pattern plate: antiskid aluminum plate, and f...Read more -

What are the factors affecting the price of aluminum ingots?

1. Supply and demand The relationship between supply and demand directly affects the market pricing of a commodity. When the relationship between supply and demand is in temporary balance, the market price of the commodity will fluctuate in a narrow range. When supply and demand are out of balanc...Read more -

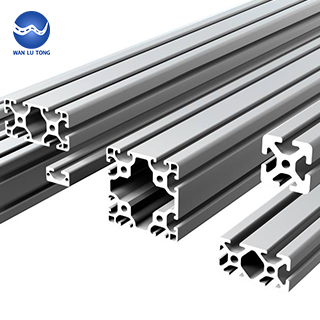

The distinction between aluminium alloy and aluminium profile?

Aluminum alloy refers to a kind of aluminum material inside, ADC12 aluminum alloy also refers to aluminum and other metals mixed into an alloy. And aluminum profile refers to the molding of the product, aluminum alloy material or pure aluminum products can be called aluminum profile. Aluminum all...Read more -

How many do you know about the surface of alloy aluminum drawing process

Metal wire drawing solution is to be done in the stamping mold, alloy aluminum plate metal wire drawing can be based on decorative design needs, made of straight lines, lines, external threads, waves and swirls and other categories. Straight wire drawing refers to the parallel lines produced by m...Read more -

The five processes of coating aluminum coil manufacturing process are described in detail

Aluminum strip is widely used in electronic devices, packaging, engineering construction, mechanical equipment and other levels. What are the main uses of aluminum strip? What is the classification of aluminum strip? Shuolin aluminum strip manufacturers to solve your doubts, we are a technical pr...Read more -

Role and process of magnesium ingot pickling

The process of removing impurities on the surface of magnesium ingot and adding anti-oxidation film. The surface of magnesium ingot is easily corroded when exposed to the atmosphere. In addition, some impurities on the surface of magnesium ingot, such as inorganic chloride flux and electrolyte, w...Read more -

Magnesium alloy characteristics and magnesium alloy product series introduction and application fields

Magnesium alloy properties The new magnesium alloy material is an alloy composed of magnesium matrix and other elements. It is known as “the greenest engineering structural material with the most potential application in the 21st century”. It has excellent properties such as low densi...Read more -

Explain in detail the casting method of aluminum rod steps for you

1. Choose the correct casting temperature The correct casting temperature is also an important factor to produce high quality aluminum bars. The forging defects such as coarse grain and feather crystal are easy to occur when the temperature is high. After grain refinement, the forging temperatur...Read more -

Classification and quality identification of high quality aluminum ingots

If a country does not have developed industry, then the country will be extremely weak, because both military industry and people’s livelihood are inseparable from the development of industry. The developed industrial system is an important cornerstone to ensure social stability and nationa...Read more -

Aluminum foil rolling characteristics

In the production of double sheet foil, aluminum foil rolling is split into three processes: rough rolling, middle rolling and finishing rolling. From the purpose of view of the method, it may be roughly divided from the rolling exit thickness. the overall classification is that the exit thicknes...Read more -

The difference between brushed aluminum plate and ordinary aluminum plate

Aluminum plate could be a rectangular plate processed by aluminum rolling, which is split into pure aluminum plate, alloy aluminum plate, thin aluminum plate, medium thick aluminum plate, brushed aluminum plate, pattern aluminum plate. Aluminum plate is widely employed in our life, we will even b...Read more